Chemical dipping tanks are a practical way of stripping coatings off objects such as wooden furniture or metalwork.

However, the chemicals used in them, if strong enough to strip or soften coatings, are almost always going to be potent enough to pose a serious health risk to the employees operating the tanks. This is something the Health and Safety Executive (HSE) takes very seriously. There are comprehensive regulations in place to control the risks.

Direct contact with the chemicals will normally be mitigated by the use of long-handled tools, protective clothing and other sensible procedures. But these chemicals evaporate too, to produce noxious vapours. If inhaled, these can have a serious short term and long term adverse effects including cancers and asthma.

Extracting vapour from chemical dipping tanks

So what can be done? Extraction is the solution and normally a legal requirement. An extraction system can capture the harmful vapours as they evaporate and remove them from your premises, so preventing them from being inhaled.

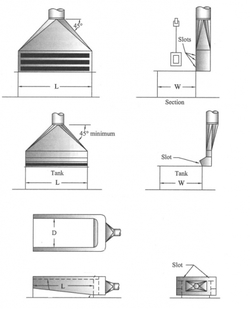

Extraction systems come in different shapes and sizes. Types which use canopies and enclosures are unlikely to be appropriate because of the access restrictions that they would pose, so lip extraction will often be the answer.

Mounted on the flange, the lip extraction slots run the full length of the tank. They capture and extract the hazardous contaminant vapours and mists rising up, and so protect the operator and other personnel.

However, there are factors that must be carefully considered when using lip extractions, as they can seriously influence the effectiveness of the system. It is best these are considered at the factory planning stage or when new or replacement tanks are proposed. Let’s explore the common issues and how to handle them.

Ensure your tank layout takes into account your extraction system

When it comes to designing proper extraction systems for chemical dipping tanks, we often find that little contingency has been allowed for extraction when the tanks were installed. Tanks may be positioned too closely together, next to walls or in close proximity to other equipment such as cranes.

This creates serious complications during the design phase of the extraction system, resulting in an extremely complex or even impossible duct route.

The answer here is to ensure that, when laying out your chemical dipping tanks, there is sufficient space between neighbouring tanks and walls. A good rule of thumb is that they should be large enough for an operator to walk between them with ease this is essential for tanks that are more than two metres in length. Doing this will prevent complications with the ducting route, and allow for easy access to inspection hatches and dampers.

Choose a tank size appropriate to your tasks

The second issue that complicates extraction that we see, is the use of oversized tanks ones that are unnecessarily big for the products being dipped. Perhaps the temptation is to plan ahead and install tanks that may meet potentially bigger work in the future. However, this can result in difficulty when trying to achieve the required face velocity to maintain control of the vapours.

There are several benefits to choosing a tank of similar size to the products being dipped. These all translate into lower set-up and running costs for the dipping process.

First it will reduce the volume of fumes being released. This will, in turn, lower the airflow rate required. And in turn this will mean a smaller fan and ducting for extraction. That all means a simpler, lower-cost extraction system.

Second, a smaller tank, of course, means less chemicals, which translates into lower running costs.

Do you need lip extraction for chemical dipping tanks?

If you need an effective lip extraction system for your chemical dipping tanks, speak to us at Vent-Tech. We can help with any or all of the design, installation, maintenance and training. Remember, the key to making the extraction process simple is to consider it at the design and planning stage of your dipping tanks. Give us a call on 01179 712 163 to find out how we can help.